How does a watermaker work?

Complete explanation of the desalination process

A watermaker, also called a reverse osmosis system, is a device that transforms seawater into fresh water. It is essential equipment for sailors and boaters who want to be self-sufficient in water during their sea voyages. But how exactly does a watermaker work? Find out here how it works and its different stages.

1. The principle of reverse osmosis

Most watermakers work through a process called reverse osmosis . This technique filters seawater through a semi-permeable membrane, retaining salt and impurities and allowing only fresh water to pass through.

Unlike natural osmosis (where water spontaneously moves from a less concentrated medium to a more concentrated medium), reverse osmosis applies high pressure to force seawater through the membrane and extract fresh water.

👉 In summary:

- Sea water is pumped and pressurized.

- It passes through specific membranes which retain salt and impurities.

- Fresh water is collected, while brine (very salty water) is discharged into the sea.

2. The different stages of operation of a desalinator

The desalination process takes place in several phases:

🔹 1. Seawater sampling

Water is drawn from outside the boat using an intake pump . This raw water contains salt, microorganisms and various impurities.

🔹 2. Pre-filtration

Before being sent under pressure, the water passes through several sediment filters designed to eliminate suspended particles (sand, algae, debris). This step is crucial to avoid damaging the membranes of the desalinator.

🔹 3. Putting under pressure

A high pressure pump is used to compress the water to about 55 to 70 bars . This pressure is needed to force the water through the membranes and separate the fresh water from the salt.

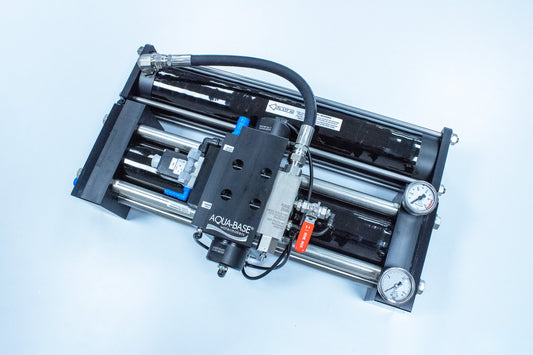

At AQUA-BASE, the high-pressure pump - the main consumer of energy - is replaced by a hydraulic amplification system powered by a low-pressure pump . This patented technology is called energy recovery . It not only allows for very low consumption , but is also remarkably quiet and vibration-free .

🔹 4. Reverse osmosis and final filtration

The pressurized water passes through a semi-permeable membrane that retains salts, bacteria and other impurities . Only pure water passes through, while very salty water (brine) is discharged through a pipe outside the boat.

🔹 5. Production and storage of fresh water

The resulting water is then sent to a fresh water tank. Some systems have post-treatment , such as an activated carbon filter to remove any traces of contaminants or improve the taste of the water.

3. Energy consumption and efficiency

A watermaker generally runs on electricity (12V, 24V, 48V or 115-230V depending on the model). Energy consumption varies depending on the production capacity:

- Small model (30-50 L/h) : consumes approximately at least 12A in 12V .

- Standard model (60-100 L/h) : consumes more than 1000 watts .

👉 For energy-autonomous boats, there are optimized models that can be powered by solar panels, wind turbines or generators.

4. Maintenance and precautions

To ensure good performance and optimal membrane life, it is essential to regularly maintain your watermaker:

✔️ Rinse with fresh water after each prolonged use to prevent salt crystallization.

✔️ Change sediment filters periodically depending on usage.

✔️ Store the membranes with a sterilant if the watermaker is not in use or during wintering.

Conclusion

A watermaker produces fresh water in the open sea using the principle of reverse osmosis . Through a series of filtrations and high pressure, it eliminates salt and impurities to provide fresh water suitable for consumption and on-board needs.

📌 Choosing the right model based on your water requirements and the power available on board is essential to optimize your navigation autonomy.